* Built-in 8 Bit Micro Processor

Advance unique software application to achieve reliable and

quality spot-weld joints.

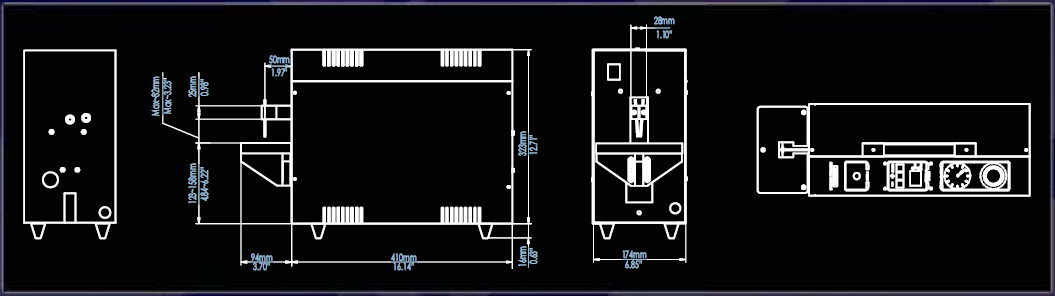

* Portable Size Design

Unique light weight with overall dimension only

50.4x17.4x33.9 cm (19.84x6.85x13.34”) (H x D x W), and

weight only 27 kgs (59.60 lbs), operated by single-phase AC

power with plug in pneumatic socket.

* Closet control Panel

Closet control panel built inside the cabinet to prevent shaking

or vibration due to operation and/or moving the equipment

around causing undesired setting occurred. The setting

method is simple. The operator requires less training and can

master the machine efficiently.

* Self-contained Digital Display and Memory Setting

Welding data is digitally set and precisely displayed. All setting

is memorized by the built-in battery free memory system.

* Pneumatic Operation

Fully pneumatic operation reduce operator(s) fatigue ensure

high productivity.

* Feasibility

Most suitable for various battery and contacts welding range

from button cell to cylindrical battery. Easy to move around

and within minutes set-up at any spot on the conveyor line. |

* Safety Alarm System

Built-in self-alarm system whenever the machine is

being misused and generated abnormal heat, the alert

sound will automatically switch "ON" to alert the operator

to stop the welding operation and have the maintenance

technician to check the machine before being further

damaged.

* Easy Maintenance

The electronic control circuit is designed with plug in

module board. In case of faulty simply switch off the

main and replace the module board to sustain production.

* Optional Automatic Power Compensation Unit Set

In the event of significant unstable or poor electricity

power network, it is highly recommend to install this

optional set. Once this APCU set is installed, the built-in

CPU frequently scans and monitors the input voltage.

Once the input voltage is up and/or down, the CPU will

trigger the APCU circuit and automatically adjust the

welding energy within millisecond to ensure steady

reliable and quality weld joints operation. |