|

The FS700-5 welding platform was designed according one of company’s patent, technologies of “TRANSFORMER OUT PUT MANIPULATION [ TOM ]”. It is a brand new welding control theory which invented by our R&D team at 2005. A latest large |

|

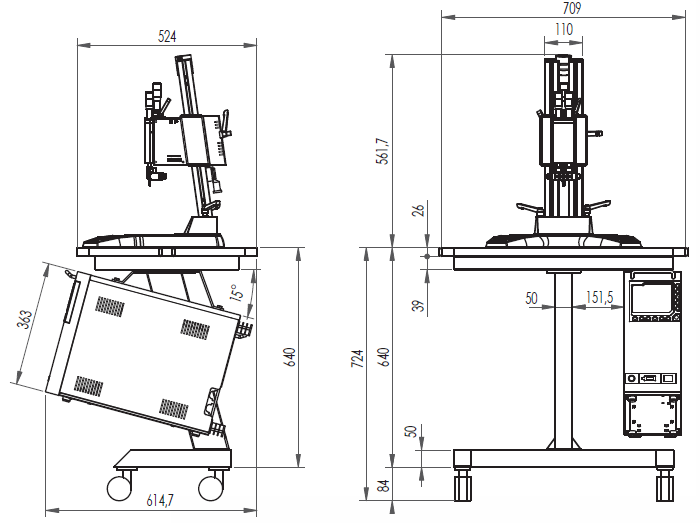

1. Patented “TOM” advance technology. 2. Ergonomically design both for performance and appearance. 3. Full color graphical display. 4. Simple on screen setting up. 5. Weld energy monitor built-in. 6. Weld patterns library for uploading. 7. Weld perimeters store and recall. 8. Bi-directional welding pulses. 9. Pre-check function. 10. Weld terminator. 11. Fine forces weld head with rapid following up. 12. Differential pressure actuating system. 13. Large working platform. 14. Tuning screw throat alignment with clearance fine tune. 15. Production flexibility. 16. Single phase power source. |

FS700-5P PNEUMATIC MODEL.. |

Features and specifications for the FC700-5, POWER UNIT and PNE BS-5 or ELE BS-5 TAB WELD HEAD, please refer to relate catalogues. |

| Protecting shield, Foot Switch and mounting, Tool Box And Tools, Electrodes And Holders, Air Input Coupler, Instruction Manual, Warranty Sheet. |

| Weld Data Carrier and CD-ROM [Part No..301-0-102] Real-time weld data output line. [Part No..301-0-105] |

*Due to our policy of continuous product improvement, the specifications are subject in change without notice.