|

Modern industry places growing emphasis on agility, the need for systems with flexibility at scales not previously possible is becoming critical. |

|

1. Patented “TOM” advance technology. 2. Ergonomically design both for performance and appearance. 3. Full color graphical display. 4. Simple on screen setting up. 5. Weld energy monitor built-in. 6. Weld patterns library for uploading. 7. Weld perimeters store and recall. 8. Bi-directional welding pulses. 9. Pre-check function. 10. Weld terminator. 11. Fine forces weld head with rapid following up. 12. Differential pressure actuating system. 13. Adapting flexible automation in tab weld. 14. Weld energy set various according battery polarities and joint location. 15. Large working platform. 16. Tuning screw throat alignment with clearance fine tune. 17. Production flexibility. 18. Single phase power source. 19. Automatic identisfly battery welding faces. 20. Electric weld head. Auto detects and adjust work clearance. |

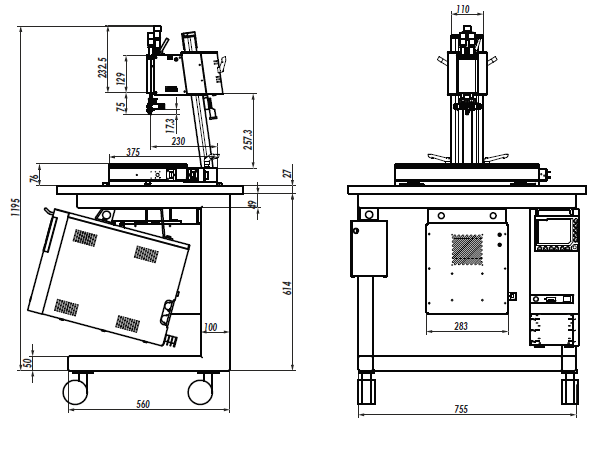

| FS1000-5P FEXTO PNEUMATIC MODEL.. 1] FC1000-5 RESISTANCE WELD CONTROL AND POWER SUPPLY. Precision “Transformer Output Manipulation [ TOM ]” power supply and control. 2] TN1000 WELD TRANSFORMER. Weld transformer hooking up with FC1000—5 power supply, provide weld current up to 10000 amperes. 3] PNE BS-5 WELD HEAD. Dual springs forced weld head with differential pressure actuation 4] FEXTO -5S TWO AXIS AC SERVO DRIVER. Two axis AC driver for X-Y working platform driving. 5] FEXTO XY-5S TWO AXIS AC SERVO X-Y WORKING PLATFORM. High speed X-Y working platform. Travel 120 x 300 mm. Repeat accuracy 0.1 mm. 6] WS-5 WORK TABLE. On wheels movable work table with stationary settlements, provided both production flexibility and operation stability. |

FS1000-5E FEXTO ELECTRIC MODEL.. 1] FC1000-5 RESISTANCE WELD CONTROL AND POWER SUPPLY Precision “Transformer Output Manipulation [ TOM ]” power supply and control. 2] TN1000 WELD TRANSFORMER. Weld transformer hooking up with FC1000—5 power supply, provide weld current up to 10000 amperes. 3] ELE BS-5 WELD HEAD. Dual springs forced weld head with stepping motor actuation 4] FEXTO -5S TWO AXIS AC SERVO DRIVER. Two axis AC driver for X-Y working platform driving. 5] FEXTO XY-5S TWO AXIS AC SERVO X-Y WORKING PLATFORM. High speed X-Y working platform. Travel 120 x 300 mm. Repeating accuracy 0.1mm. 6] WS-5 WORK TABLE. On wheels movable work table with stationary |

| Protecting shielf, Foot Switch and mounting, Tool Box And Tools, Electrodes And Holders, Air Input Coupler, Instruction Manual, Warranty Sheet. |

| 1. Photoelectric safety sensor. [ Part No 302-0-104 ]. 2. Weld Data Carrier And CD-ROM. [Part No..301-0-102] 3. Real-time weld data output line. [Part No..301-0-105] |

| Features and specifications of FC1000-5 POWER SUPPLY and TN1000 WELD TRANSFORMER, PNE BS-5 or ELE BS-5 TAB WELD HEAD, FEXTO S-3 DRIVE and XY-5S PLATFORM please refer to relate catalogues. |

*Due to our policy of continuous product improvement, the specifications are subject in change without notice.