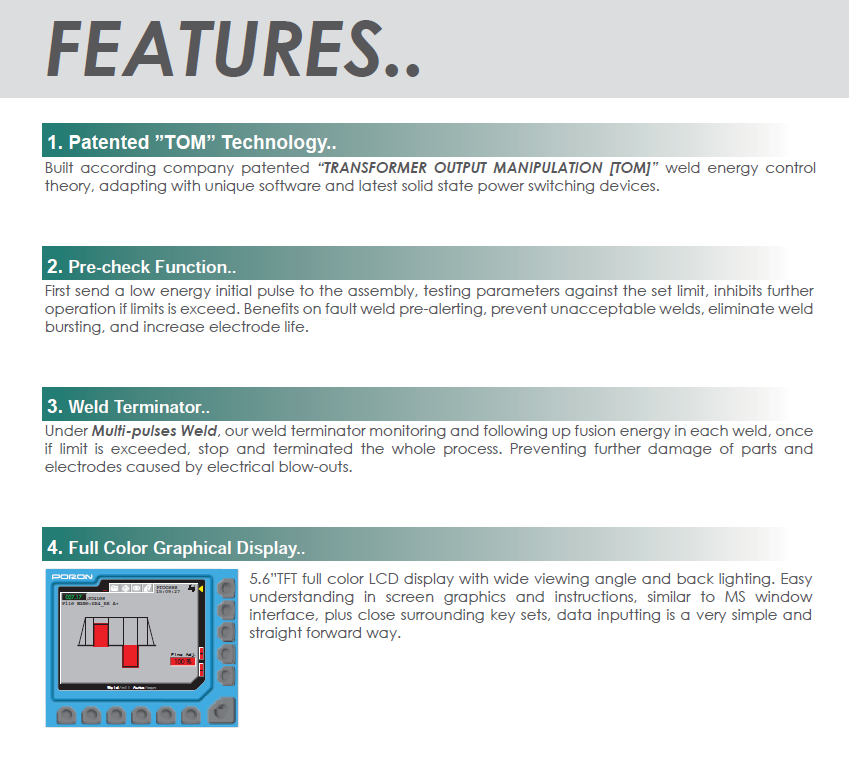

The FC SERIES power unit was designed according our company patented paper “Transformer Output Manipulation [ TOM ] “, the latest energy

control technology for resistance welding. With combination both benefits of high frequency weld and capacitor discharge weld, the [TOM]

welder can generate a high level of weld current as well as provided a very precise control of weld curve.

Thanks for the technique of “Transformer Output Manipulation [ TOM ] ”, the weld power and timing in the unit can be set individually as ultra-fast

hard weld or longer time soft weld, ultra-fast weld permit very shot weld times, resulting in less part deformation and provided better out looking.

This is extremely important when welding heat sensitive parts such as miniature battery cell or heat sensitive electronic device.

There are different welding curves storing in the machine memory, working for quality joints, the operator are recommended to select a suitable

weld pattern form stocking for the application, these weld curves are chosen various according materials, thickness and surface finishing both

on tabs and batteries. On other hand, the weld energy unit also monitoring by a built-in with a weld monitor, energy consumption taken in each

weld was carefully calibrated. Once if weld data was recorded and calculate as ‘out of range”, alert signals will generate, so as weld operation

been temperatally stopped, until the trouble was fully alerted and cleared than reset by the operator, experiential record... The system can be

successfully screened out up to 0.01% of un-qualify joints during mass production.

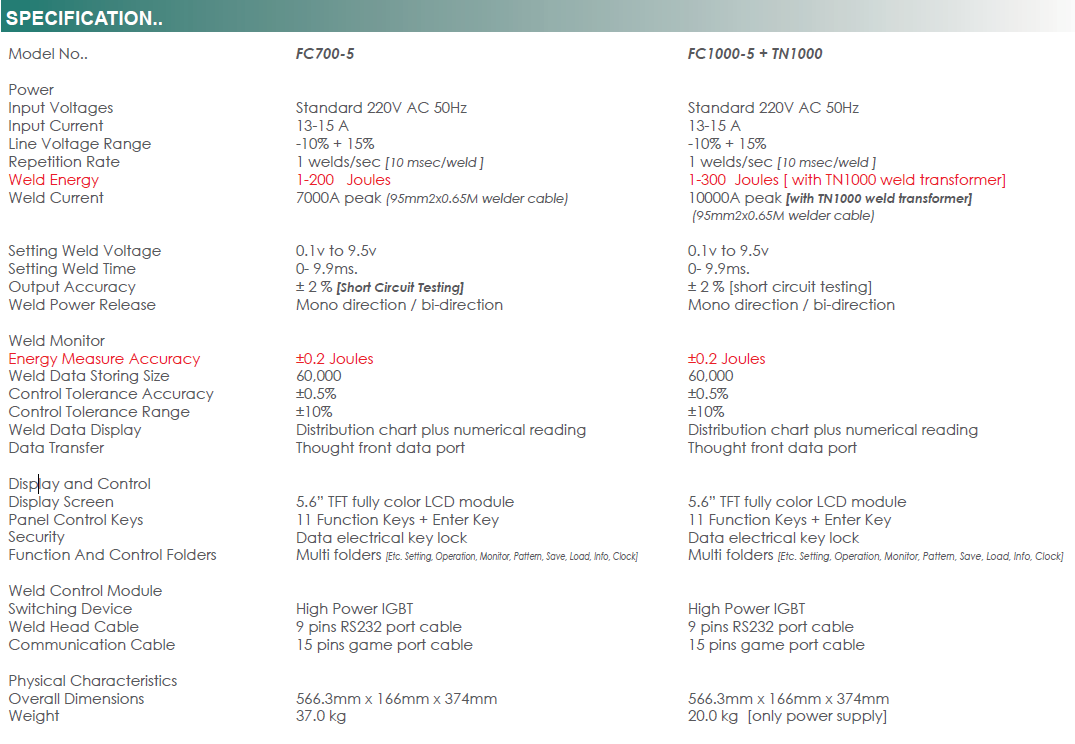

The FC SERIES power unit is ideal for micro joining and battery tab welding application, requires only single phase input power, the current output

of FC700-5 is 7000 Amperes, however FC1000-5 if adapted with TN 1000 weld transformer the output current is up to 10000 amperes. It can linking

up with different weld heads to from a welding station, which suitable both for precision spot or battery tab welding, also the unit was designed

operating in high speed,with extremely satisfaction of weld repeating rates and perfectly reliable, it is an ideal tool to gear up with industrial

automation.