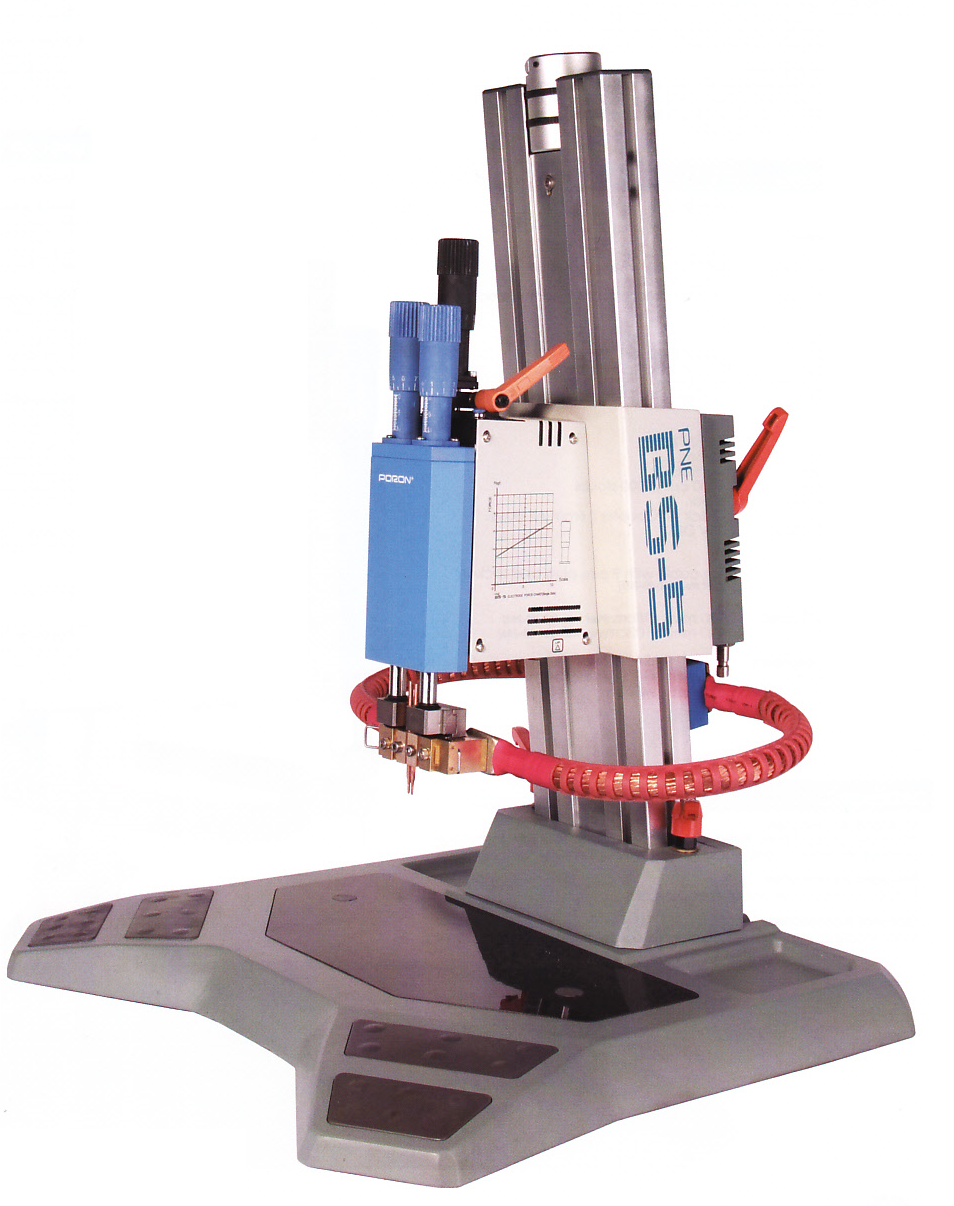

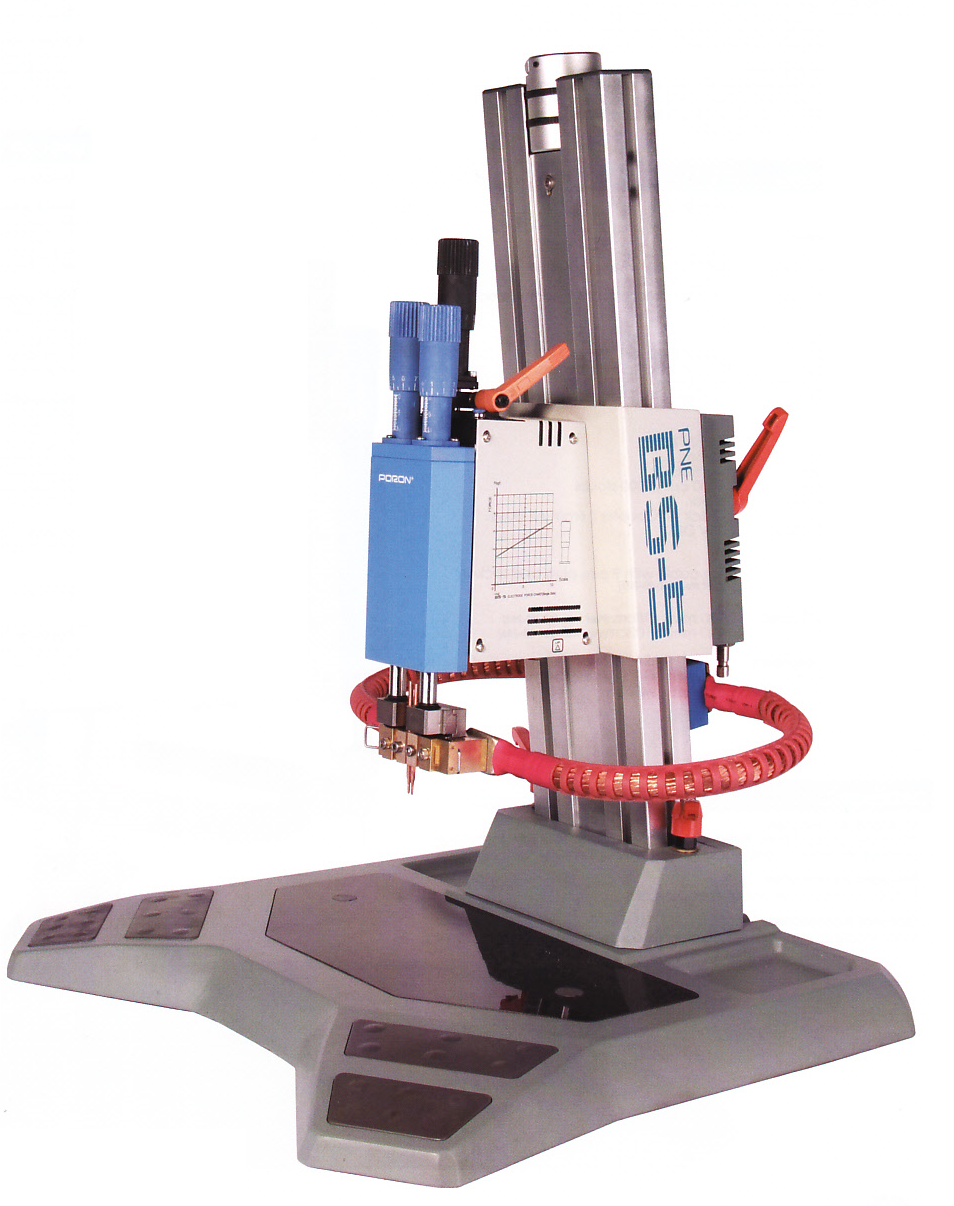

PNE BS-5 weld head is a perfect tool for precision

tab welding applications, it was designed working

together with power unit FC700-5 or combined a

work bench WS-3 and formed FS700-5 weld station.

The equipment consists of two low inertia electrode

holders both suspending on frictionless linear ball

bearing columns, weld forces applying are by

means of compressed springs through a pair of fine

force adjusting screw knobs to the joints, this

arrangement fully considered stability of welding

force as well as provided an excellent effect for

electrode force following up, which are most

important key factors in resistance weld process.

Movement of weld head is fully controlling by our

unique DPCS “Differential Pressure Control System”.

During operation, the DPCS system will

automatically minimizes the weight of weld head at

the same time eliminated exceed impact caused

by down velocity momentum.

Thanks for the helps of ergonomic engineering, the

PNE BS-5 was perfectly considered human and

machine factors, our design philosopher is base on

easy handling and minimize of human fatigue.

Equipped with a large area working platform,

where various sizes pads or weld fixture can placed

on and operating comfortably, the height of weld

head can adjusted to 270mm, large / long size

batteries or the connection are in row can be

successfully insert into the throat without problem.

The weld head is moves by a fold lever turn knob

locating on the top, through the driving fine pitch

lead screw, weld head can adjust to any decided

working clearance.

|

|