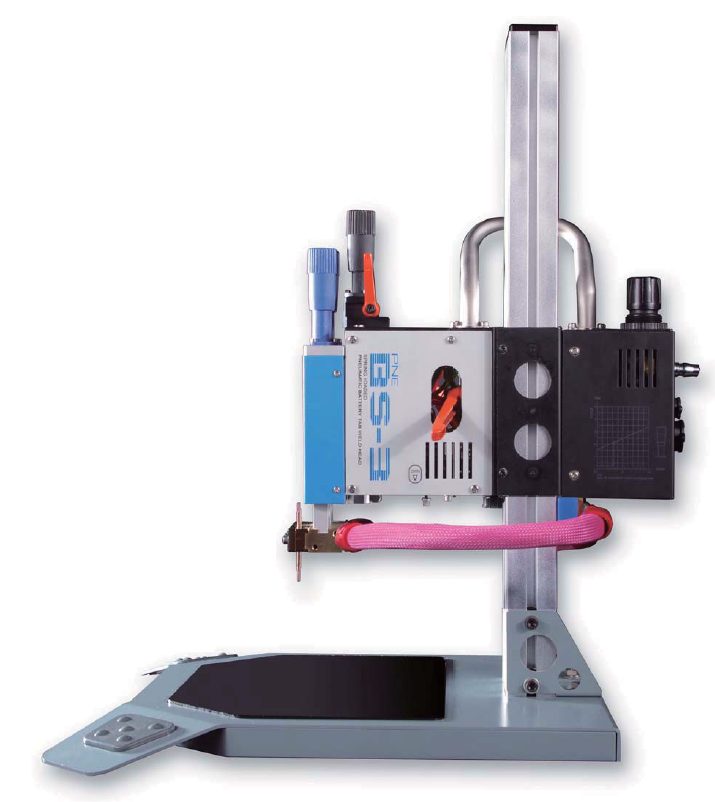

1. Ergonomically Design Both For Performance And Appearance..

Design fully considered five aspects of ergonomics, Safety, Comfort, Easy for use,

Productivity/performance, and Aesthetic appeal.

2. Fine Weld Force With Rapid Following Up..

Spring loaded fine adjustment of preset welding forces, provides a very stable in

welding pressure, low inertia and frictionless linear ball guide ways actuating a quick

following up force during metal fashioning, which is a important factor for reducing weld

sparks and improved joint quality.

3. Both Pneumatic And Motor Drive Models Are Available.

Pneumatic weld head PNE BS-3 is simply and economical model, suitable for general

purpose manual operation. However, motor head ELE BS-3 is perfectible for high speed

or frequently operation, it’s flexibility of speed adapting and fully controllable features,

make it idea for large lot size production as well as for industrial automation.

4. Large Work Table With Long Throat..

Large operation platform suitable for jointing over size pads or batteries adapting with

weld fixture. Long work stroke alignment, the machine is perfectly handling long

batteries or for cells connecting as cylindrical rod shape.

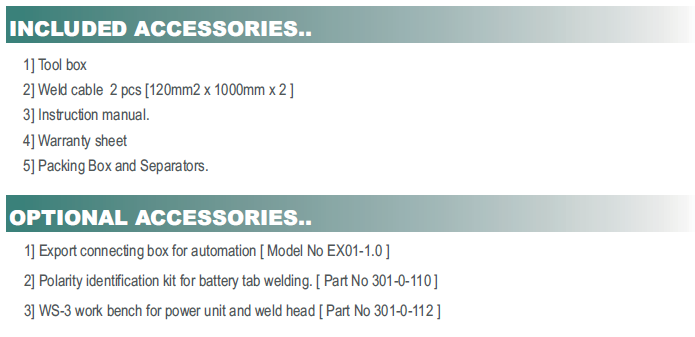

5. Designed For Bench Work And Automation..

The BS-3 is a standing alone weld head mostly use for bench operation. Working with

automation, an optional Export connecting box for automation [ Model No EX01-1.0 ] is

recommended to add with PLC controller, after linked up, all in/out signals can be

passing through bidirectionally, so it is ideally working with PLC controller, as a

precision resistance weld power supply adapting for industrial automation.

Our standard model,weld head and stand can easy remove from it’s base by simply

loosen it from lock screws and relocated it on the bed of automatic machine.

6. Air Spring Suspension Of Height Adjustment.

Weld head is suspending on a weight balance air spring cylinder inserted in the

supporting column, height adjustment can simply be done by push and pull the

handrails locating on the top and side of the weld head, through the help of auxiliary

force from the driven air spring, weld head can easy and fast adjust to any decided

height.

7. Battery Polarities Identification. [ Optional ]

BS-3 can be adapt with an optional polarity identify sensor kit [ part no 301-0-110 ] and

magnetic battery base locator, since positive or negative ends of every cells was

determined by magnets inserted into the base locator, once signal was picking up by

the sensor under the machine base, identification signal will input into the power unit

and control, system immediately verified the weld is taking place on the battery positive

or negative ends, various energies preset according polarities will automatically release

to weld the joint. Benefit of this function is.. Every weld energies are customizated

according weld conditions, symptom of loose weld and over welded will no longer arise.. |